Company Profile

YPAK PACKAGING GROUP was established in 2011 and formed with 3 companies based on Hongkong, Dongguan and Foshan. We have become one of the largest coffee bag manufacturers in China. We use the best quality WIPF valves from Switzerland to keep your coffee fresh.

Conform to the plastic ban policy imposed to many different countries, we have researched and developed the sustainable packaging bags, such as RECYCLABLE and COMPOSTABLE pouches.

No minimum quantity, no color plates are required with our HP 25K INDIGO DIGITAL PRINTING service.

Our mission is to protect the environment by using our eco-friendly material food packaging pouches.

You are welcome to visit YPAK.

Our History

2012

In May 2012, the first complete flexible packaging production line.

2016

In March 2016, began to produce flat bottom bags.

2017

In August 2017, the second production line was established.

2018

April 2018, using solvent-free composite technology.

2020

In June 2020, the automatic ink adjustment system was introduced.

2020

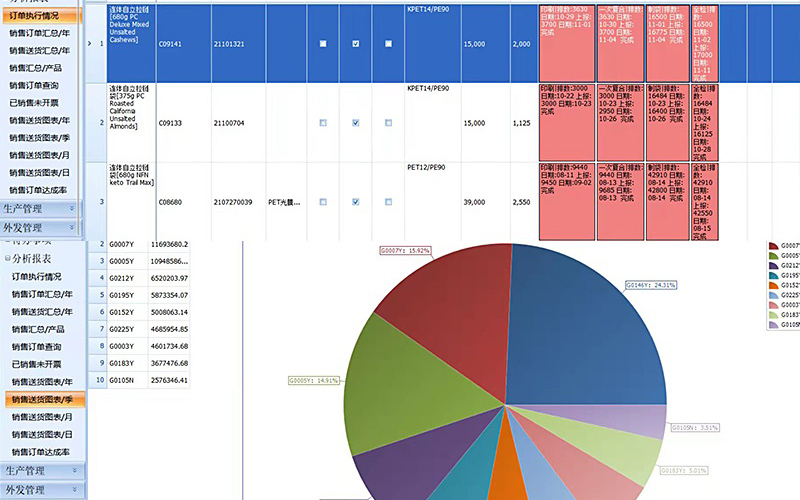

In July 2020, the ERP production system was introduced.

2021

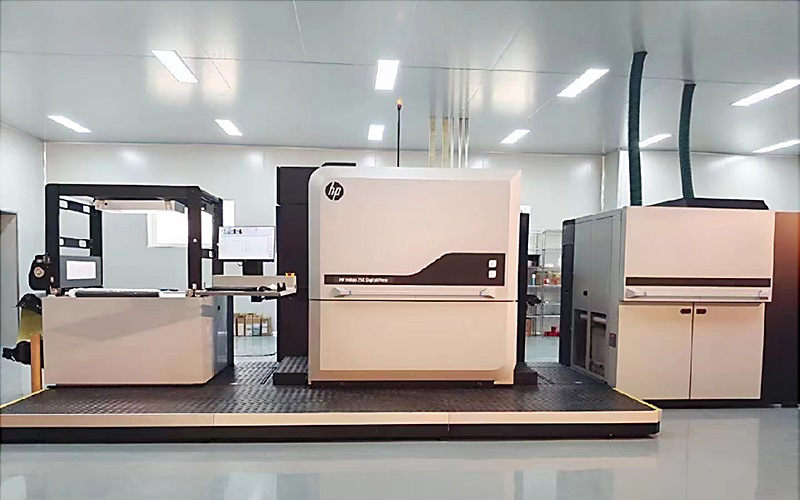

In October 2021, HP INDIGO 25K digital printing machine was be introduced.

Rotogravure printing, also known as gravure printing, is a popular method in the printing industry and offers many advantages. This printing technology is widely used in flexible packaging bags, food packaging bags, coffee bags, etc. and is ideal for the packaging industry.

One of the greatest advantages of rotogravure printing is its excellent image quality. The printing process involves engraving an image onto a cylinder, which is then transferred to the desired material. This enables high-resolution and detailed images to be printed onto the bags, presenting designs and product information with absolute precision.

In addition to image quality, gravure printing also offers excellent color reproduction. Engraving rollers allow consistent and accurate application of ink to material. This results in vibrant and vivid colors that help products stand out on store shelves and make them more visually appealing to consumers.

Another advantage of rotogravure printing is its versatility. It can be used on a variety of materials including different types of plastics, films and papers. This makes them ideal for flexible packaging bags as they need to be able to withstand a wide range of environmental conditions while providing effective protection for the goods inside. Whether it is food packaging bags, coffee bags or any other type of flexible packaging, rotogravure printing can be easily adapted to the specific requirements of each product.

In terms of efficiency, rotogravure excels in high-volume production. Its printing speed is fast, and a large number of packaging bags can be produced in a short time. This is especially beneficial for businesses that require a large number of bags to meet supply needs. Gravure printing ensures that products can be packaged and delivered in a timely manner, helping companies meet customer expectations and maintain a competitive advantage in the market.

In addition, gravure printing bags have excellent durability. The ink is embedded deeply into the material, creating a strong bond that resists fading, scratching and moisture damage. This ensures that the pouch can withstand handling, shipping and storage without compromising its visual appeal. Customers can trust that their products will be well protected and maintain their high-quality appearance throughout the supply chain.

In conclusion, gravure printing has a wide range of advantages, making it an excellent choice for flexible packaging bags, food packaging bags and coffee bags. Its superior image quality, color reproduction, versatility and efficiency make it the method of choice for businesses in the packaging industry. Additionally, the durability offered by gravure bags ensures that products remain visually appealing and well protected from production to consumption. With the growing demand for high-quality packaging solutions, gravure printing has emerged as a reliable and effective option for businesses looking to enhance packaging design and protect products.

HP INDIGO 25K DIGITAL PRESS

In the ever-evolving world of packaging, businesses are constantly looking for ways to stand out and leave a lasting impression on consumers. With the growing demand for personalized and eye-catching packaging, digital printing has become a game-changer for the industry. Today we will discuss the advantages of digital printing for flexible packaging bags such as coffee and food packaging bags.

In the ever-evolving world of packaging, businesses are constantly looking for ways to stand out and leave a lasting impression on consumers. With the growing demand for personalized and eye-catching packaging, digital printing has become a game-changer for the industry. Today we will discuss the advantages of digital printing for flexible packaging bags such as coffee and food packaging bags.

One of the significant advantages of HP Indigo 25K Digital Press, is its ability to deliver high-quality, vibrant and detailed prints. This results in stunning packaging that effortlessly grabs the customer's attention. Whether it's intricate designs, vibrant colors or lifelike images, digital printing ensures that every detail on the bag comes to life. This level of quality helps the product stand out on store shelves and instantly capture the interest of potential buyers.

In addition, digital printing offers unparalleled flexibility. Unlike traditional printing methods, digital printing offers businesses the ability to print small batches and change designs anytime, anywhere. This advantage is especially useful for small businesses or businesses that need to rebrand occasionally. Using digital printing, there is no need to print packaging bags in batches, reducing the risk of wasting resources due to excessive inventory. This cost-effective approach enables businesses to maintain dynamic and responsive packaging solutions that easily adapt to market trends and consumer preferences.

In addition to flexibility, digital printing also offers faster turnaround times compared to traditional printing methods. With the HP Indigo 25K Digital Press, businesses can dramatically reduce the time it takes to go from packaging design to final production. This quick turnaround is critical for businesses operating in fast-paced markets where time is of the essence. Digital printing enables businesses to respond quickly to market demands, launch new products quickly, and make modifications in real time, ensuring they stay ahead of the competition and maximize sales potential.

In addition, digital printing of flexible packaging bags is environmentally friendly. Traditional printing methods often involve the use of harmful chemicals and excessive waste. However, digital printing greatly reduces these negative effects. It requires fewer chemicals and generates less waste, helping businesses reduce their carbon footprint and contributing to sustainable practices.

The HP Indigo 25K Digital Press is designed for flexible packaging, ensuring excellent ink adhesion and durability. This means that printing on coffee bags, food bags and other flexible packaging solutions is resistant to fading, staining and moisture damage. High-quality printing and long-lasting durability build trust and credibility with consumers, reassuring them of the freshness and quality of the product.

In summary, with cutting-edge technologies HP Indigo 25K Digital Press, offers many advantages for flexible packaging bags. High-quality printing, flexibility, fast turnaround and environmental sustainability make digital printing the first choice for businesses looking to create attractive packaging. By utilizing digital printing, businesses can stay relevant, adapt to market fluctuations, and ultimately increase brand recognition and sales. So why settle for ordinary packaging when digital printing can transform your product into something extraordinary?

Solvent-free Lamination Machines

In the food and beverage industry, packaging plays a vital role in ensuring the quality, safety and freshness of products delivered to consumers. In recent years, flexible packaging has been favored for its versatility, low cost, and environmental friendliness. In this industry, solvent-free laminators have been a game-changer, revolutionizing the way food packaging, including coffee packaging, is done. At YPAK, we pride ourselves on offering state-of-the-art solvent-free laminators to print your packaging bags.

So, why should you choose a solvent-free lamination to print your bags. Let's delve into the advantages they bring.

First, solvent-free laminators offer unrivaled safety. Traditional solvent-based lamination techniques often involve the use of hazardous substances such as toluene and ethyl acetate, which pose serious health risks to operators and can contaminate packaged foods. In contrast, solvent-free lamination eliminates these toxic chemicals, ensuring the safety and integrity of the packaging process from start to finish.

Second, the solvent-free laminator offers excellent quality. The absence of solvents allows for a more precise and controlled lamination process, resulting in exceptionally sharp and vibrant prints on packaging films. Whether it's a bold logo on a coffee bag or a beautiful design on a snack bag, our solvent-free laminators ensure your brand's visual appeal stands out from the competition.

Additionally, solvent-free laminators promote sustainability and are more environmentally friendly. By eliminating solvents, these machines significantly reduce emissions of volatile organic compounds (VOCs), known contributors to air pollution and climate change. As the demand for environmentally friendly packaging continues to soar, choosing a solvent-free laminator demonstrates your commitment to sustainability and can enhance your brand reputation.

In addition to these advantages, solvent-free laminators also increase efficiency and productivity. The solvent-free drying process speeds up production, resulting in shorter turnaround times and higher yields. This is especially beneficial for industries such as coffee packaging, where fast delivery and freshness are paramount. With our advanced solvent-free laminator, you can streamline operations and easily meet customer needs.

As a customer-oriented company, our priority is to provide tailor-made solutions to meet your specific needs. Our team of experts will work closely with you to understand your packaging requirements, whether it is food or coffee, and recommend the most suitable solvent-free laminating machine to achieve your desired results. We understand the unique challenges facing the flexible packaging industry, and our commitment to innovation and customer satisfaction sets us apart from the competition.

Solvent-free laminator has revolutionized packaging with its safety, superior quality, environmental sustainability and increased efficiency. Trust us to provide you with the latest in solvent-free lamination technology and exceptional customer service as we continue to lead the way in this ever-evolving industry. Contact us today and let us help you take your packaging to the next level.

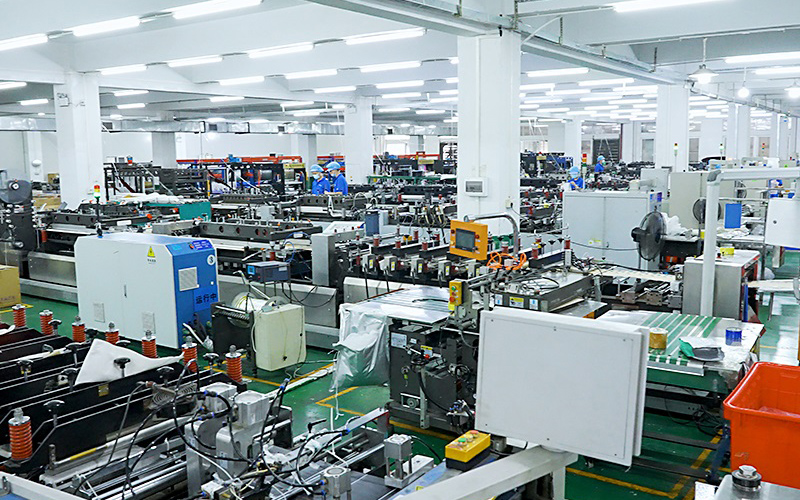

With the growing demand for flexible packaging bags in the food and beverage industry, the need for efficient bag making machines has become critical. Bag making machines are an integral part of the manufacturing process, producing high-quality bags that meet the industry's stringent standards. We will explore the importance of efficient bag making machines in the flexible packaging bag industry, with a special focus on food and coffee packaging bags.

Flexible packaging bags are widely used in the food industry due to their ability to protect contents, extend shelf life and provide convenient storage and shipping options. As consumer demand for ready-to-eat meals, snacks and even coffee continues to increase, the need for efficient packaging solutions becomes critical. This is where bag making machines come into play.

Bag making machines are designed to process flat material such as plastic or aluminum into bags of various shapes and sizes. The efficiency of these machines directly affects the throughput, product quality and overall cost-effectiveness of the packaging process. Therefore, for enterprises in the flexible packaging bag industry, it is imperative to invest in an efficient bag making machine.

Thanks to technological advancements, modern bag making machines offer various features to optimize the production process. The machines are equipped with precise temperature control, adjustable sealing parameters and quick changeover capabilities, allowing manufacturers to easily switch between different bag sizes and designs. Additionally, they are often equipped with automated systems that can detect and correct any errors in the manufacturing process, thereby significantly reducing the chances of defective products.

For food packaging bags, maintaining product freshness is crucial. An efficient bag making machine ensures an airtight seal that prevents any external factors like moisture and oxygen from affecting the quality and shelf life of the food. Whether preserving the aroma and flavor of coffee or extending the shelf life of perishable foods, bag making machines play a vital role in ensuring the integrity and safety of packaged goods.

Our efficient bag making machines not only increases productivity, but also enables companies to meet the ever-changing demands of consumers. The ability to quickly produce high-quality pouches enables businesses to launch new products, offer custom packaging solutions, and even implement innovative marketing strategies to differentiate themselves in the market.

Our efficient bag making machine is a game changer in the flexible packaging bag industry. Food and coffee packaging requires precision, reliability and speed to meet consumer demands and maintain product freshness. With our advanced bag making machines, companies can optimize production processes, improve product quality, and gain a competitive advantage in the market. As the industry continues to evolve, adopting technological advancements in bag making machines is key to staying ahead in the evolving landscape of the food packaging industry.