How to detect the quality of aluminum foil packaging bags

•1. Observe the appearance: The appearance of the aluminum foil packaging bag should be smooth, without obvious flaws, and without damage, tearing or air leakage.

•2. Smell: A good aluminum foil packaging bag will not have a pungent smell. If there is a smell, it may be that inferior materials are used or the production process is not standardized.

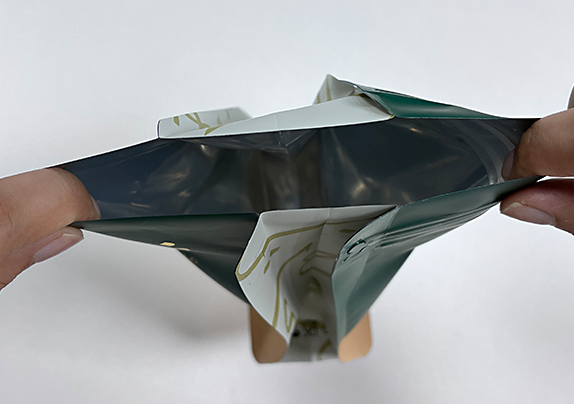

•3. Tensile test: You can stretch the aluminum foil packaging bag to see if it breaks easily. If it breaks easily, it mean•s the quality is not good.

•4. Heat resistance test: Put the aluminum foil packaging bag into a high temperature environment and observe whether it deforms or melts. If it deforms or melts, it means the heat resistance is not good.

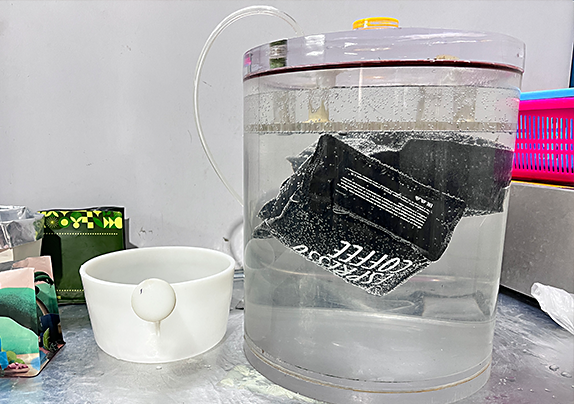

•5. Moisture resistance test: Soak the aluminum foil packaging bag in water for a period of time and observe whether it leaks or deforms. If it leaks or deforms, it means the moisture resistance is not good.

•6. Thickness test: You can use a thickness meter to measure the thickness of aluminum foil packaging bags. The greater the thickness, the better the quality.

•7.Vacuum test: After sealing the aluminum foil packaging bag, perform a vacuum test to see if there is any pain or deformation. If there is air leakage or deformation, the quality is poor.

Post time: Oct-11-2023