Iphrofayela Yenkampani

I-YPAK PACKAGING GROUP yasungulwa ngo-2011 futhi yasungulwa nezinkampani ezi-3 ezisekelwe eHongkong, Dongguan naseFoshan. Sesibe ngomunye wabakhiqizi abakhulu bezikhwama zekhofi eChina. Sisebenzisa amavalvu ekhwalithi engcono kakhulu ye-WIPF evela eSwitzerland ukuze sigcine ikhofi lakho lilisha.

Ngokuvumelana nenqubomgomo yokuvinjelwa kwepulasitiki ebekwe emazweni amaningi ahlukene, senze ucwaningo futhi sathuthukisa izikhwama zokupakisha ezisimeme, ezifana nezikhwama ze-RECYCLABLE kanye ne-COMPOSTABLE.

Awekho ubuningi obuncane, awekho amapuleti ombala adingekayo ngesevisi yethu ye-HP 25K INDIGO DIGITAL PRINTING.

Umgomo wethu ukuvikela imvelo ngokusebenzisa izikhwama zethu zokupakisha ukudla ezivumelana nemvelo.

Wamukelekile ukuthi uvakashele i-YPAK.

Umlando Wethu

2012

Ngo-May 2012, umugqa wokuqala ophelele wokukhiqiza wokupakisha oguquguqukayo.

2016

Ngo-March 2016, waqala ukukhiqiza izikhwama flat phansi.

2017

Ngo-Agasti 2017, umugqa wesibili wokukhiqiza wasungulwa.

2018

Ephreli 2018, kusetshenziswa ubuchwepheshe obuhlanganisiwe obungancibiliki.

2020

NgoJuni 2020, kwethulwa uhlelo lokulungisa uyinki oluzenzakalelayo.

2020

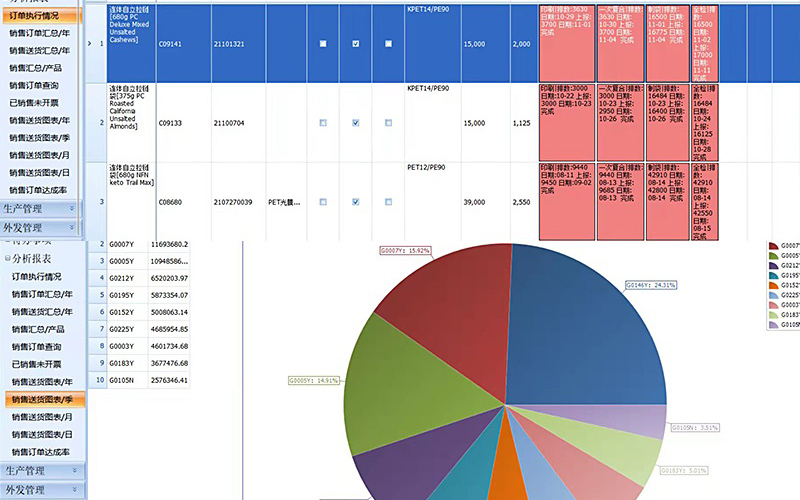

NgoJulayi 2020, kwethulwa uhlelo lokukhiqiza lwe-ERP.

2021

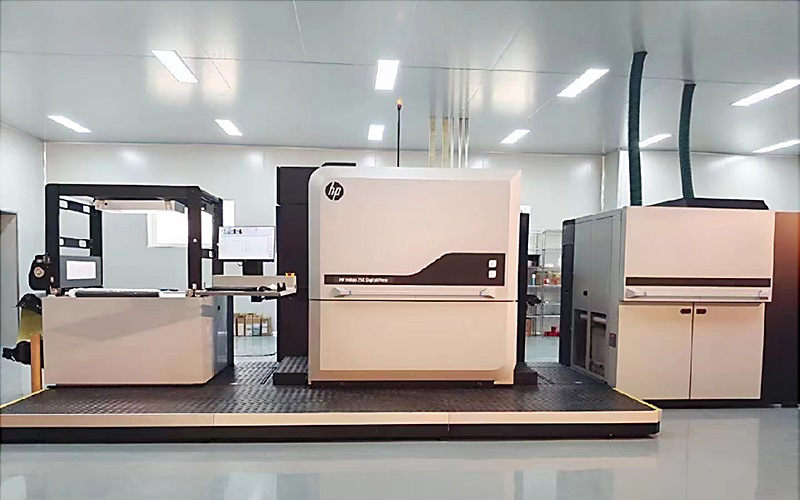

Ngo-Okthoba 2021, kwethulwa umshini wokuphrinta wedijithali we-HP INDIGO 25K.

I-Rotogravure printing, eyaziwa nangokuthi i-gravure printing, iyindlela ethandwayo embonini yokunyathelisa futhi inikeza izinzuzo eziningi. Lobu buchwepheshe bokuphrinta busetshenziswa kakhulu ezikhwameni zokupakisha eziguquguqukayo, izikhwama zokufaka ukudla, izikhwama zekhofi, njll. futhi zilungele imboni yokupakisha.

Enye yezinzuzo ezinkulu zokuphrinta kwe-rotogravure yikhwalithi yayo yesithombe esihle kakhulu. Inqubo yokunyathelisa ihlanganisa ukuqoshwa kwesithombe kusilinda, esibe sesidluliselwa kulokho okufunayo. Lokhu kuvumela izithombe ezinokulungiswa okuphezulu kanye nemininingwane eminingi ukuthi ziphrintwe ezikhwameni, ukwethula imiklamo kanye nolwazi lomkhiqizo ngokunemba okuphelele.

Ngaphezu kwekhwalithi yesithombe, ukuphrinta kwe-gravure nakho kunikeza ukukhiqizwa kombala okuhle kakhulu. Amarola aqoshiwe avumela ukusetshenziswa okungaguquguquki nokunembile kukayinki kokubalulekile. Lokhu kubangela imibala egqamile futhi egqamile esiza imikhiqizo igqame emashalofini esitolo futhi iyenze ikhange nakakhulu kubathengi.

Enye inzuzo yokuphrinta kwe-rotogravure ukuguquguquka kwayo. Ingasetshenziswa ezintweni ezihlukahlukene ezihlanganisa izinhlobo ezahlukene zamapulasitiki, amafilimu namaphepha. Lokhu kuzenza zibe zilungele izikhwama zokupakisha eziguquguqukayo njengoba zidinga ukuthi zikwazi ukumelana nezimo eziningi zemvelo ngenkathi zihlinzeka ngokuvikeleka okuphumelelayo kwempahla ngaphakathi. Kungakhathaliseki ukuthi izikhwama zokupakisha ukudla, izikhwama zekhofi noma yiluphi olunye uhlobo lokupakisha oluguquguqukayo, ukuphrinta kwe-rotogravure kungashintshwa kalula kuzidingo ezithile zomkhiqizo ngamunye.

Ngokuphathelene nokusebenza kahle, i-rotogravure ihamba phambili ekukhiqizeni ivolumu ephezulu. Ijubane layo lokuphrinta liyashesha, futhi inani elikhulu lezikhwama zokupakisha lingakhiqizwa ngesikhathi esifushane. Lokhu kunenzuzo ikakhulukazi emabhizinisini adinga inani elikhulu lezikhwama ukuze ahlangabezane nezidingo zokuhlinzeka. Ukuphrinta kwe-Gravure kuqinisekisa ukuthi imikhiqizo ingapakishwa futhi ilethwe ngesikhathi, kusize izinkampani ukuthi zihlangabezane nokulindelwe ngamakhasimende futhi zigcine inzuzo yokuncintisana emakethe.

Ngaphezu kwalokho, izikhwama zokunyathelisa ze-gravure zinokuqina okuhle kakhulu. Uyinki ugxiliswe ngokujulile ezintweni, udala isibopho esiqinile esimelana nokufiphala, ukuklwebheka kanye nokulimala komswakama. Lokhu kuqinisekisa ukuthi isikhwama singakwazi ukumelana nokuphathwa, ukuthunyelwa nokugcinwa ngaphandle kokuphazamisa ukubukeka kwaso. Amakhasimende angathemba ukuthi imikhiqizo yawo izovikeleka kahle futhi igcine ukubukeka kwayo kwekhwalithi ephezulu kulo lonke uchungechunge lokuhlinzeka.

Sengiphetha, ukuphrinta kwe-gravure kunezinhlobonhlobo zezinzuzo, okwenza kube yisinqumo esihle kakhulu sezikhwama zokupakisha eziguquguqukayo, izikhwama zokupakisha ukudla nezikhwama zekhofi. Ikhwalithi yayo yesithombe ephezulu, ukukhiqizwa kombala, ukuguquguquka nokusebenza kahle kuyenza ibe indlela yokuzikhethela emabhizinisini embonini yokupakisha. Ukwengeza, ukuqina okunikezwa izikhwama ze-gravure kuqinisekisa ukuthi imikhiqizo ihlala ibukeka kahle futhi ivikelwe kahle kusukela ekukhiqizeni kuya ekusetshenzisweni. Ngokukhula kwesidingo sezisombululo zokupakisha ezisezingeni eliphezulu, ukuphrinta kwe-gravure kuye kwavela njengendlela ethembekile nephumelelayo yamabhizinisi afuna ukuthuthukisa ukwakheka kokupakisha nokuvikela imikhiqizo.

I-HP INDIGO 25K DIGITAL PRESS

Ezweni lokupakisha elihlala livela, amabhizinisi ahlala efuna izindlela zokugqama futhi ashiye umbono ongapheli kubathengi. Ngokukhula kwesidingo sokupakishwa komuntu siqu nokudonsa amehlo, ukuphrinta kwedijithali sekushintshe umdlalo embonini. Namuhla sizoxoxa ngezinzuzo zokuphrinta kwedijithali kwezikhwama zokupakisha eziguquguqukayo ezifana nekhofi nezikhwama zokupakisha zokudla.

Ezweni lokupakisha elihlala livela, amabhizinisi ahlala efuna izindlela zokugqama futhi ashiye umbono ongapheli kubathengi. Ngokukhula kwesidingo sokupakishwa komuntu siqu nokudonsa amehlo, ukuphrinta kwedijithali sekushintshe umdlalo embonini. Namuhla sizoxoxa ngezinzuzo zokuphrinta kwedijithali kwezikhwama zokupakisha eziguquguqukayo ezifana nekhofi nezikhwama zokupakisha zokudla.

Enye yezinzuzo ezibalulekile ze-HP Indigo 25K Digital Press, amandla ayo okuletha amaphrinti ekhwalithi ephezulu, agqamile futhi anemininingwane. Lokhu kubangela ukupakishwa okumangalisayo okudonsa ukunaka kwekhasimende kalula. Noma ngabe imiklamo eyinkimbinkimbi, imibala egqamile noma izithombe ezifana nempilo, ukuphrinta kwedijithali kuqinisekisa ukuthi yonke imininingwane esesikhwameni iyaphila. Leli zinga lekhwalithi lisiza umkhiqizo ukuthi ugqame emashalofini esitolo futhi ubambe ngokushesha intshisekelo yabathengi abangaba khona.

Ngaphezu kwalokho, ukuphrinta kwedijithali kunikeza ukuguquguquka okungenakuqhathaniswa. Ngokungafani nezindlela zendabuko zokuphrinta, ukuphrinta kwedijithali kunikeza amabhizinisi ikhono lokuphrinta amaqoqo amancane futhi ashintshe imiklamo noma kunini, noma kuphi. Le nzuzo iwusizo ikakhulukazi kumabhizinisi amancane noma amabhizinisi adinga ukushintshwa kabusha ngezikhathi ezithile. Ukusebenzisa ukuphrinta kwedijithali, asikho isidingo sokuphrinta izikhwama zokupakisha ngamaqoqo, ukunciphisa ingozi yokumosha izinsiza ngenxa yokusungula ngokweqile. Le ndlela engabizi kakhulu yenza amabhizinisi akwazi ukugcina izixazululo zokupakisha ezinamandla nezisabelayo ezijwayelana kalula namathrendi emakethe nokuthandwa ngabathengi.

Ngaphezu kokuguquguquka, ukuphrinta kwedijithali nakho kunikeza izikhathi zokushintsha ngokushesha uma kuqhathaniswa nezindlela zokuphrinta zendabuko. Nge-HP Indigo 25K Digital Press, amabhizinisi anganciphisa ngokumangazayo isikhathi asithathayo ukusuka ekwakhiweni kokupakisha ukuya ekukhiqizweni kokugcina. Lokhu kushintsha okusheshayo kubalulekile kumabhizinisi asebenza ezimakethe ezisheshayo lapho isikhathi siwumongo. Ukuphrinta kwedijithali kwenza amabhizinisi aphendule ngokushesha ezidingweni zemakethe, ethule imikhiqizo emisha ngokushesha, futhi enze izinguquko ngesikhathi sangempela, aqinisekise ukuthi ahlala ngaphambi komncintiswano futhi andise amathuba okuthengisa.

Ngaphezu kwalokho, ukuphrinta kwedijithali kwezikhwama zokupakisha eziguquguqukayo kuhambisana nemvelo. Izindlela zokunyathelisa zendabuko ngokuvamile zihilela ukusetshenziswa kwamakhemikhali ayingozi kanye nemfucumfucu eyeqisayo. Nokho, ukuphrinta kwedijithali kunciphisa kakhulu le miphumela emibi. Idinga amakhemikhali ambalwa futhi ikhiqize imfucuza encane, isiza amabhizinisi ehlise i-carbon footprint yawo futhi ibe negalelo emikhubeni eqhubekayo.

I-HP Indigo 25K Digital Press yakhelwe ukupakishwa okuvumelana nezimo, iqinisekisa ukunamathela kukayinki okuhle kakhulu nokuqina. Lokhu kusho ukuthi ukuphrinta ezikhwameni zekhofi, izikhwama zokudla kanye nezinye izixazululo zokupakisha eziguquguqukayo zimelana nokufiphala, ukubola kanye nokulimala komswakama. Ukuphrinta kwekhwalithi ephezulu nokuqina okuhlala isikhathi eside kwakha ukwethenjwa nokuthembeka kubathengi, kubaqinisekisa ngobusha nekhwalithi yomkhiqizo.

Kafushane, ngobuchwepheshe obuphambili i-HP Indigo 25K Digital Press, inikeza izinzuzo eziningi zezikhwama zokupakisha eziguquguqukayo. Ukuphrinta kwekhwalithi ephezulu, ukuguquguquka, ukushintsha ngokushesha kanye nokusimama kwemvelo kwenza ukuphrinta kwedijithali kube yinketho yokuqala kumabhizinisi afuna ukwakha amaphakheji akhangayo. Ngokusebenzisa ukuphrinta kwedijithali, amabhizinisi angahlala efanelekile, azivumelanise nokuguquguquka kwemakethe, futhi ekugcineni andise ukuqashelwa komkhiqizo nokudayiswa. Ngakho-ke kungani ulungele ukupakishwa okujwayelekile lapho ukuphrinta kwedijithali kungaguqula umkhiqizo wakho ube into engavamile?

Imishini yokuLamination engancibilikisiwe

Embonini yokudla neziphuzo, ukupakishwa kudlala indima ebalulekile ekuqinisekiseni ikhwalithi, ukuphepha kanye nokusha kwemikhiqizo elethwa kubathengi. Eminyakeni yamuva nje, ukupakishwa okuguquguqukayo kuye kwathandwa ngenxa yokuguquguquka kwayo, izindleko eziphansi, kanye nobungane bemvelo. Kulo mkhakha, ama-laminator angenawo ancibilikisiwe abe ushintshi wegeyimu, aguqula indlela okupakishwa ngayo ukudla, okuhlanganisa ukupakishwa kwekhofi, okwenziwa ngayo. Kwa-YPAK, siyaziqhenya ngokunikeza ama-laminator asezingeni eliphezulu angancibiliki ukuze siphrinte izikhwama zakho zokupakisha.

Ngakho-ke, kungani kufanele ukhethe i-lamination engena-solvent ukuze uphrinte izikhwama zakho. Ake sihlole izinzuzo ezilethwayo.

Okokuqala, ama-laminator angenayo i-solvent anikeza ukuphepha okungenakuqhathaniswa. Amasu okuncibilikisa asuselwa kuncibilikisi evamile ngokuvamile ahilela ukusetshenziswa kwezinto eziyingozi njenge-toluene ne-ethyl acetate, ezibeka ubungozi obukhulu bezempilo kubaqhubi futhi ezingangcolisa ukudla okupakishiwe. Ngokuphambene, i-lamination engena-solvent iqeda la makhemikhali anobuthi, iqinisekisa ukuphepha nobuqotho benqubo yokupakisha kusukela ekuqaleni kuya ekupheleni.

Okwesibili, i-laminator engena-solvent inikeza ikhwalithi enhle kakhulu. Ukungabi khona kwezincibilikisi kuvumela inqubo enembe kakhudlwana futhi elawulwayo yokucwenga, okuholela ekubhalweni okubukhali nokugqamile kumafilimu okupakisha. Kungakhathaliseki ukuthi ilogo egqamile esikhwameni sekhofi noma idizayini enhle esikhwameni sokudla okulula, ama-laminator ethu angancibiliki aqinisekisa ukukhanga okubonakalayo komkhiqizo wakho kugqama emqhudelwaneni.

Ukwengeza, ama-laminator angenayo i-solvent akhuthaza ukusimama futhi anobungani bemvelo. Ngokuqeda izinto ezincibilikisayo, le mishini inciphisa kakhulu ukukhishwa kwezinto eziphilayo ezishintshashintshayo (VOCs), abanegalelo abaziwayo ekungcoleni komoya nokushintsha kwesimo sezulu. Njengoba isidingo sokupakisha esivumelana nemvelo siqhubeka sikhula, ukukhetha i-laminator engancibiliki kukhombisa ukuzibophezela kwakho ekusimameni futhi kungathuthukisa isithunzi somkhiqizo wakho.

Ngaphezu kwalezi zinzuzo, ama-laminator angenayo i-solvent nawo andisa ukusebenza kahle nokukhiqiza. Inqubo yokomisa engancibilikiyo isheshisa ukukhiqizwa, okuholela ezikhathini ezimfushane zokushintsha kanye nesivuno esiphezulu. Lokhu kunenzuzo ikakhulukazi ezimbonini ezifana nokupakishwa kwekhofi, lapho ukulethwa okusheshayo nokusha kubaluleke kakhulu. Nge-laminator yethu ethuthukisiwe engena-solvent, ungakwazi ukuhlela imisebenzi futhi uhlangabezane kalula nezidingo zamakhasimende.

Njengenkampani egxile kumakhasimende, okuhamba phambili kwethu ukuhlinzeka ngezixazululo ezenzelwe ukuhlangabezana nezidingo zakho ezithile. Ithimba lethu lochwepheshe lizosebenza eduze nawe ukuze baqonde izidingo zakho zokupakisha, kungakhathaliseki ukuthi ukudla noma ikhofi, futhi batusa umshini wokugcwalisa i-laminating ongena-solvent ofaneleka kakhulu ukuze uzuze imiphumela oyifunayo. Siyaziqonda izinselele eziyingqayizivele ezibhekene nemboni yokupakisha evumelana nezimo, futhi ukuzibophezela kwethu ekusunguleni izinto ezintsha nokwaneliseka kwamakhasimende kusenza sihluke emqhudelwaneni.

I-solvent-free laminator iguqule ukupakishwa kwayo ngokuphepha kwayo, ikhwalithi ephezulu, ukusimama kwemvelo kanye nokusebenza kahle okwandisiwe. Sithembe ukuthi sizokuhlinzeka ngolwazi lwakamuva lobuchwepheshe be-lamination obungenayo i-solvent kanye nesevisi yamakhasimende eyingqayizivele njengoba siqhubeka nokuhola phambili kulo mkhakha ohlale uvela. Xhumana nathi namuhla futhi sikuvumele sikusize ukuthi uthathe ukupakisha kwakho ukuyise kwelinye izinga.

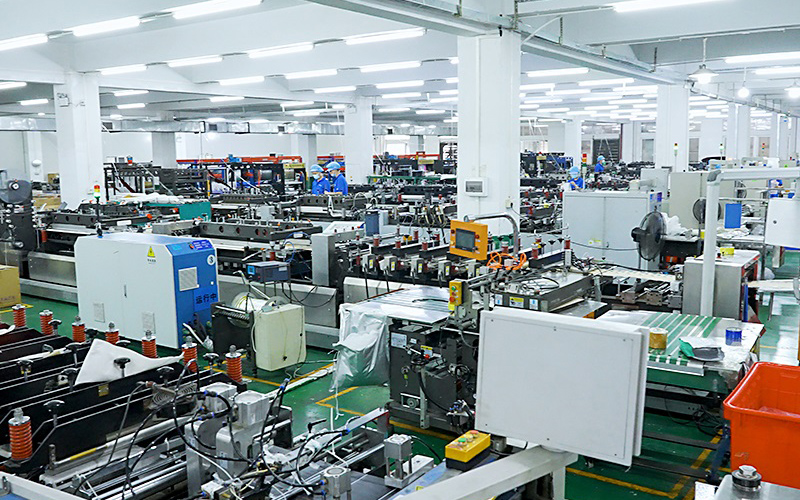

Ngokukhula kwesidingo sezikhwama zokupakisha eziguquguqukayo embonini yokudla neziphuzo, isidingo semishini ephumelelayo yokwenza izikhwama sesibucayi. Imishini yokwenza izikhwama iyingxenye ebalulekile yenqubo yokukhiqiza, ekhiqiza izikhwama zekhwalithi ephezulu ezihlangabezana nezindinganiso eziqinile zemboni. Sizohlola ukubaluleka kwemishini ephumelelayo yokwenza izikhwama embonini yezikhwama zokupakisha eziguquguqukayo, ngokugxila okukhethekile ezikhwameni zokudla nekhofi.

Izikhwama zokupakisha eziguquguqukayo zisetshenziswa kakhulu embonini yokudla ngenxa yekhono lazo lokuvikela okuqukethwe, ukunweba impilo yeshalofu futhi zinikeze isitoreji esilula nezinketho zokuthumela. Njengoba isidingo sabathengi sokudla osekulungele ukudliwa, ukudla okulula ngisho nekhofi siqhubeka nokwanda, isidingo sezixazululo ezisebenzayo zokupakisha siba bucayi. Yilapho imishini yokwenza izikhwama iqala ukusebenza khona.

Imishini yokwenza izikhwama iklanyelwe ukucubungula izinto eziyisicaba ezifana nepulasitiki noma i-aluminium zibe izikhwama zomumo nosayizi abahlukahlukene. Ukusebenza kahle kwale mishini kuthinta ngqo ukusebenza, ikhwalithi yomkhiqizo kanye nokusebenza kahle kwezindleko zenqubo yokupakisha. Ngakho-ke, kumabhizinisi asembonini yezikhwama zokupakisha eziguquguqukayo, kubalulekile ukutshala emshinini wokwenza izikhwama osebenza kahle.

Ngenxa yentuthuko yezobuchwepheshe, imishini yesimanje yokwenza izikhwama inikeza izici ezihlukahlukene zokuthuthukisa inqubo yokukhiqiza. Imishini ifakwe ukulawula izinga lokushisa okunembile, imingcele yokuvala eguquguqukayo kanye nekhono lokushintsha ngokushesha, okuvumela abakhiqizi ukuthi bashintshe kalula phakathi kosayizi bezikhwama ezahlukene kanye nemiklamo. Ukwengeza, bavame ukuhlonyiswa ngamasistimu azenzakalelayo angakwazi ukubona futhi alungise noma yimaphi amaphutha enqubweni yokukhiqiza, ngaleyo ndlela ehlisa kakhulu amathuba emikhiqizo enesici.

Ezikhwameni zokupakisha ukudla, ukugcina ubusha bomkhiqizo kubalulekile. Umshini osebenza kahle wokwenza isikhwama uqinisekisa isivalo esingangenisi umoya esivimbela noma yiziphi izici zangaphandle njengomswakama nomoya-mpilo ukuthi zingathinti ikhwalithi nempilo yeshelufu yokudla. Kungakhathaliseki ukuthi ilondoloza iphunga nephunga lekhofi noma yandisa isikhathi seshelufu sokudla okonakalayo, imishini yokwenza izikhwama idlala indima ebalulekile ekuqinisekiseni ubuqotho nokuphepha kwezimpahla ezipakishiwe.

Imishini yethu yokwenza izikhwama ephumelelayo ayigcini nje ngokukhulisa umkhiqizo, kodwa futhi yenza izinkampani zikwazi ukuhlangabezana nezidingo ezihlala zishintsha zabathengi. Ikhono lokukhiqiza ngokushesha izikhwama zekhwalithi ephezulu lenza amabhizinisi ethule imikhiqizo emisha, anikeze izixazululo zokupakisha ngokwezifiso, futhi asebenzise namasu amasha okumaketha ukuze azihlukanise emakethe.

Umshini wethu osebenza kahle wokwenza izikhwama uwushintsho lomdlalo embonini yezikhwama zokupakisha eziguquguqukayo. Ukupakishwa kokudla nekhofi kudinga ukunemba, ukwethembeka kanye nesivinini ukuze kuhlangatshezwane nezidingo zabathengi kanye nokugcina ubusha bomkhiqizo. Ngemishini yethu ethuthukisiwe yokwenza izikhwama, izinkampani zingakwazi ukuthuthukisa izinqubo zokukhiqiza, zithuthukise ikhwalithi yomkhiqizo, futhi zithole inzuzo yokuncintisana emakethe. Njengoba imboni iqhubeka nokuvela, ukwamukela intuthuko yezobuchwepheshe emishinini yokwenza izikhwama kubalulekile ukuze uhlale uphambili esimweni esithuthukayo semboni yokupakisha ukudla.